Choosing the Right Brake Pad for the Right Customer

There is one simple piece of advice I try to live by: “Know what you know, and know what you don’t know.” This simple credo can save you from making mistakes and looking like a complete idiot.

I am often asked for my opinion of a certain brand or application of brake pads, or which I prefer. I always feel awkward when answering these questions. While I have performed a large number of brake jobs and visited more brake pad engineering and manufacturing facilities than most people, it’s difficult to give an answer people want to hear, or one I am completely comfortable giving.

I’m not a brake pad Pope who can give a blessing to one manufacturer or another. I also can’t condemn an entire country’s brake pad production. I have often found blanket statements about one type of material or another can get you in a lot of trouble as they are often inaccurate and overgeneralizations. One of the most underutilized resources for information about brake pads is the parts store counterman or counterwoman. They aren’t engineers or technicians, but they can tell you what gets the most returns and what sells the best.

In a perfect world, I could measure Mµ levels, SAE testing numbers or stopping distances from 60 mph, but this isn’t the case.

The engineering and appearance of the product matter, but most of all it’s about trust and reputation.

Pad Selection

Selecting the right friction material is a difficult task. I could say that you should select the most expensive pad that your supplier offers, but the right pads for the customer are not always at the top or bottom of the price column. Prices are irrelevant when a customer comes back complaining of noise or after the brakes have failed or developed a problem.

Selecting the right friction material is a difficult task. I could say that you should select the most expensive pad that your supplier offers, but the right pads for the customer are not always at the top or bottom of the price column. Prices are irrelevant when a customer comes back complaining of noise or after the brakes have failed or developed a problem.

What makes one friction material quieter or better than another? It is a two-part answer.

First, if a friction material is better at keeping a constant coefficient of friction across broad temperature ranges and environmental conditions, it probably is a quiet pad.

A “consistent” friction material causes less vibrational excitation variation at the friction coupling by having consistent brake torque at environmental extremes of humidity and temperature (-40º F to 500º F).

Appearance And Reputation

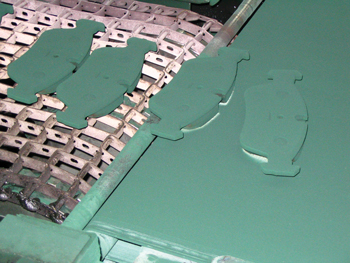

If you are going to judge a brake pad by its appearance, there are three areas you need to look at. First, look at the material used to make the shim. If the material is not a sandwich of metal, rubber or other composite material, the manufacturer could be trying to pull a fast one. Throw the shim on the floor. If it makes any rattles or pings, do not use that pad.

The foundation of any brake pad is the backing plate. If you need a hammer or a great deal of force to install the pad in the caliper bracket, it could be a sign that the tooling for the backing plate is worn out. If the tooling die that was used to stamp the backing plate was worn out, the ears and other contact points will increase in size or become distorted.

If a company is not willing to spend money on the foundation of their product, it’s not a good sign for the rest of the pad.

Look at the reputation of the company. Can you get someone on the phone from the manufacturer? Do they advertise in related trade publications? What are they willing to do to get your business?

Most of all, try the brake pads for yourself. If you are willing to put them on your own vehicle, you might feel better about selling them to your customers.

What is OE and how does it apply to brake pads?

What is OE and how does it apply to brake pads?

For the past few years, the phrase “Meets OE ______” has been used in nearly every marketing campaign in the replacement parts industry. Some companies even use it to sell wiper blades. But, it is still part of the mindset of technicians that OE equals quality.

There was a recent false advertising lawsuit between two aftermarket manufacturers concerning the OE seal of quality. The defendant printed the claim “Meets OE Requirements” in its marketing materials. The plaintiff just wanted to get the company in the courtroom so they could make them produce documents from the OEs outlining the requirements.

The plaintiff knew the defendant could not produce the documents because OEs do not make these requirements available to the general public or the automotive industry. Some doubt they even exist.

To add to the confusion, new car dealers are now selling a secondary, or less expensive line, with their OE’s name on the box for brakes and other parts.

Once, it was believed the dealer part was the direct replacement that matched what was originally on the car. The new “good” offerings have some techs asking what are we buying, and what is the real meaning of OE?

I hate to break this to a lot of shop owners and technicians, but, in my estimation, when you are buying a brake pad set from a new car dealer, you usually are not getting the exact pad that was installed on the vehicle when it was assembled.

Sure, if the vehicle is a new platform, chances are that within the first year of production the pads sitting on the dealer’s shelves might be the exact pad from the assembly line. But, after a certain period of time, those pads will be replaced by pads that are close, but not the exact pad. This is called an Original Equipment Supplier (OES) pad.

Factory installed brake pads can be very expensive because the OE is willing to spend money to have quiet brakes because brake noise complaints cost a lot of money. An OE engineer once told me that the amount of money spent on preventing brake noise makes the cost of the unintended acceleration problem look like chump change.

The most expensive part of a factory-installed pad is the friction material, but the testing and engineering of the pads are also very expensive. These costs can push the price of the pad well past ultra-premium brake pad territory.

Chances are that OES pad will not be the same pad, or even manufacturer. It will be close to the OE pad because, in some cases, the OE is willing to share design and engineering specifications with the OES supplier.

The Secret Sauce of Friction

How the components in the friction material shear, break and interact during braking can determine a pad’s friction level, noise and wear characteristics.

A brake pad may require up to 20 different raw materials. Some raw components of a friction material are abrasive, while other components lubricate. Some components, like structural fibers and resins, hold the pad together, while other components tune the friction levels through various temperature ranges.

Tuning the components in a brake pad mix is like tuning a graphic equalizer on a stereo for the best sound. This is the secret art of friction material formulation and why some pad manufacturers protect their recipes like Coke or KFC’s seven secret herbs and spices.

Ceramic

Ceramic pads’ structural properties are very stable under high temperatures, much like Corning cookware, but that is where the comparison ends.

Ceramic pads’ structural properties are very stable under high temperatures, much like Corning cookware, but that is where the comparison ends.

Ceramic materials that go into a brake pad are very small strands that are engineered to be a certain length and width.

There are three advantages of ceramic pads in certain applications. First, since the ceramic materials offer stable performance under a wide range of temperatures, they can offer quiet performance. Second, ceramic brake pads manage heat in the caliper better on some vehicles than some non-ceramic applications. Third, ceramic brake dust doesn’t show up on or stick to wheels like some other brake pad formulations. This could be an important factor if you have an expensive set of custom wheels.

NAO

Non-asbestos organic (NAO) friction materials typically wear more than harder semi-metallic compounds. Generalizing about the wear characteristics of NAO and ceramic-based compounds is difficult because there are so many variations. Wear varies depending on the formula the friction supplier chooses for a particular application.

Different vehicles require different coefficients of friction, so formulas are often “application engineered” to deliver the best combination of stopping power, wear resistance, pedal feel and noise control. Most premium-quality NAO and ceramic-based linings will provide long life and wear less than an equivalent set of NAO pads on the same application.

Semi-Metallic

Semi-metallic pads use metal fibers to give structure and provide friction. The metals used are typically high-quality steel, copper and other exotic metals.

The other part of the semi-metallic mix is a variety of materials like glues, lubricants and structural fibers. The manufacturer will blend the components together to give the best performance for that application.

Application Vehicle?Specific?Lines

If all of the material jargon is too much to deal with, you can look for a line that touts itself as vehicle or application specific. These lines can help you leave the material selection up to the manufacturer.

2016-08-24 22:53:03

ADD:No. 1, Xiaban, Xiufeng Village, Shekou Town, Fu'an City, Ningde City, Fujian Province TEL:0086-0593-6388368||6558596 FAX:0086-0593-6338966 E-mail:brake@fjhuari.com / huari3348@126.com

Copyright ? 2013 Fujian Huari Automotive Parts Co., Ltd. All Rights Reserved.

Copyright ? 2013 Fujian Huari Automotive Parts Co., Ltd. All Rights Reserved.